Related Links

ApplicationsA tube punching machine is specialized equipment designed to create precise holes in cylindrical or tubular metal materials such as pipes, tubes, and hollow sections. This process involves using a die and punch system engineered to maintain the tube’s structural integrity while producing clean, accurate cutouts.

Purpose

The primary function of a tube punching machine is to punch holes into round or square tubes without deforming or damaging the tubular shape. This enables the addition of mounting points, fastener holes, or other custom cutouts necessary for assembly and fabrication.

Application:

Benefits

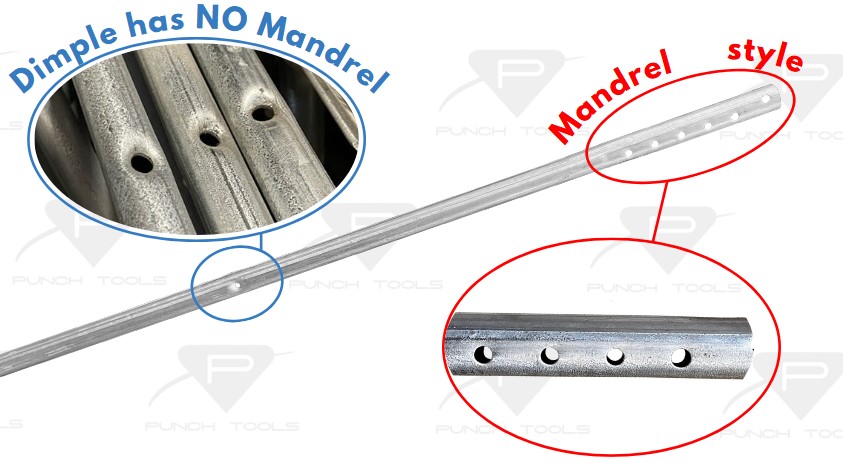

There are 2 principal methods of tube punching. Click on the following bullets to find out more!